Matrox AltiZ 3D profile sensors take gold in prestigious international competition

MONTREAL, Quebec—16 June 2020—Matrox® Imaging, established and trusted supplier to top machine vision OEMs and integrators for more than 40 years, announced today that its recently introduced Matrox AltiZ 3D profile sensors were recognized among the best in machine vision today by the judges of the Vision Systems Design 2020 Innovators Awards program. The judging panel consisted of esteemed experts from system integrator and end-user companies.

Engineered for excellence in reproduction fidelity

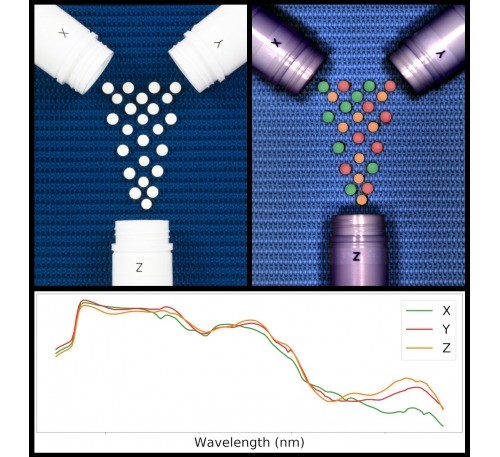

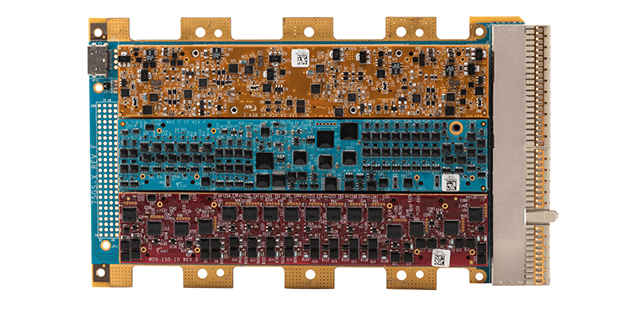

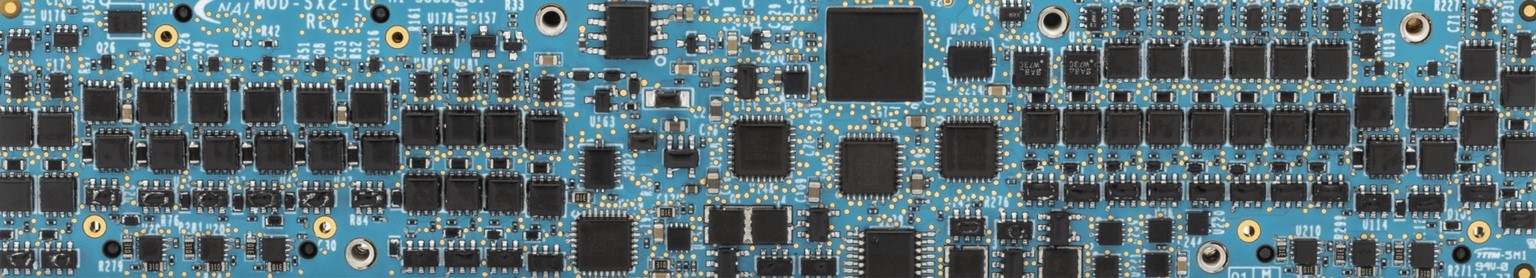

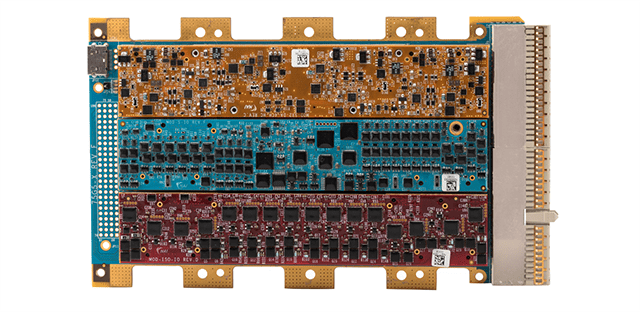

Matrox AltiZ is a series of high-fidelity 3D profile sensors, each featuring a dual-camera single-laser design that greatly lessens scanning gaps encountered at critical surface junctures because of optical occlusions. Unique algorithms running inside the sensor automatically generate various type of reliable 3D data in the form of individual profiles, depth maps, or point clouds.

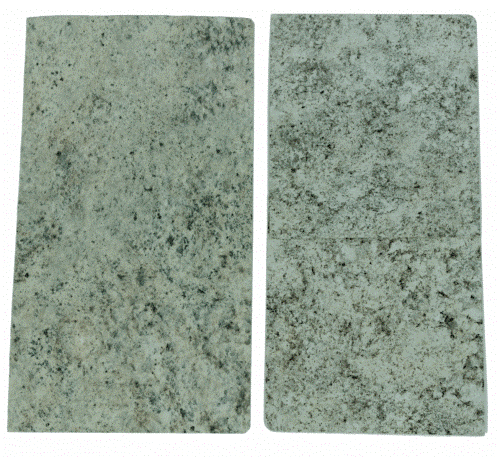

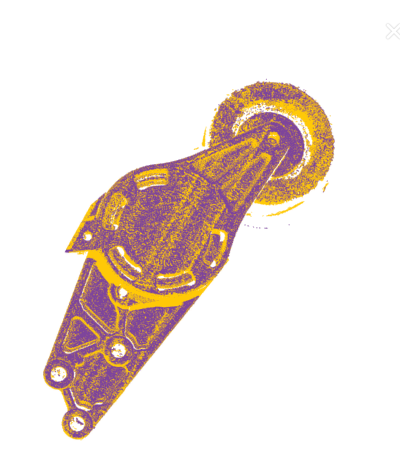

Designed and optimized for inspection, measurement, and guidance tasks, these unique 3D profile sensors use the principle of laser triangulation to generate faithful digital representation of an object or scene in three dimensions. This allows the Matrox AltiZ to capably perform surface inspections, part identification, gap and flush evaluation, bead inspection and measurement, and inline metrology, among other applications.

Perfect triangulation of performance, price, and innovation

Matrox AltiZ distinguish themselves from other 3D profile sensors in several crucial manners. Their unique dual-camera design achieves what common 3D profile sensors cannot match with one laser and a single camera. Dealing with occlusions using single-camera 3D profile sensors necessitates two sensors installed head to head, whereas Matrox AltiZ attains superior image fidelity owing to its dual-camera architecture. This design likewise permits Matrox AltiZ to work in either synchronized or alternate fashion; the former mode provides maximum reproduction quality and robustness, while the latter delivers a scanning rate almost twice that of the former while still defending against occlusion. A standard GigE Vision® interface with GenICam™ extensions was implemented to ensure interoperability with as wide a range of Matrox Imaging-branded and third-party machine vision software and controllers as possible, so as not to tie users to a proprietary interface and associated hardware and software. Finally, an embedded algorithm running directly inside each Matrox AltiZ sensor ensures greater control over spurious data—such as from reflections of the laser beam line—and results in more robust 3D reproductions. The embedded processing with data fusion avoids the additional computational demands when using common 3D profile sensors to combat the occlusion phenomena.

Award-winning Matrox AltiZ 3D profile sensors are ideally suited for markets such as automotive manufacturing, electronics and semiconductor production, wood inspection, food and beverage production and packaging, logistics and warehousing, consumer goods inspection, medical device manufacturing, and pharmaceutical production.

“The Vision Systems Design team would like to congratulate Matrox Imaging for their score in the 2020 Innovators Awards program,” says John Lewis, Editor in Chief, Vision Systems Design. “Each year this unbiased and increasingly competitive program aims to celebrate the most innovative products and systems in machine vision. The Matrox Imaging team should be very proud.”

“We are honored that the Matrox AltiZ’s innovative attributes were recognized by Vision Systems Design,” says Laval Tremblay, vice-president of engineering, Matrox Imaging. “Designed expressly to meet market demand for exceptional 3D reproduction fidelity, these unique 3D sensors are testament to significant research and development from our team of engineers. Matrox Imaging is thrilled to count this series in our renowned product lineup.”

Availability

Matrox AltiZ will begin shipping in July 2020.

About The Vision Systems Design 2020 Innovators Awards program

The Vision Systems Design 2020 Innovators Awards program reviews and recognized the most innovative products and services in the vision and image processing industry. High-scoring companies were announced via webcast on June 16. Criteria used in the Innovators Awards ranking included: originality, innovation; impact on designers, systems integrators and end-users; fulfilling a need in the market that hasn’t been addressed, leveraging a novel technology, and increasing productivity.

About Vision Systems Design

Published since 1996, Vision Systems Design is a global resource for engineers, engineering managers and systems integrators that provides comprehensive global coverage of vision systems technologies, applications, and markets. Vision Systems Design’s magazine, website (www.visionsystems.com) , email newsletters and webcasts report on and analyze the latest technology and business developments and trends in the worldwide machine vision and image processing industry.

About Matrox Imaging

Matrox Imaging is an established and trusted supplier to top OEMs and integrators involved in machine vision, image analysis, and medical imaging industries. The components consist of smart cameras, 3D sensors, vision controllers, I/O cards, and frame grabbers, all designed to provide optimum price-performance within a common software environment. For more information, visit www.matrox.com/imaging.

Matrox imaging available in Canada through partner Integrys, www.integrys.com.