Founded in 1955 and based in Bohemia, New York, North Atlantic Industries (NAI) is a leading independent designer and manufacturer of rugged embedded electronic and computing systems, power supplies and motion simulation and measurement instruments for military, commercial aerospace and industrial applications.

Remarkably successful in bringing quality, innovative products to market and delivering superior value and exemplary service, NAI’s customer base includes renowned companies/organizations such as:

- Boeing

- Northrop Grumman

- Raytheon

- Honeywell

- Lockheed Martin

- General Dynamics

- U.S. Army

- NASA

- Airbus

A testament to their extensive product portfolio, dedicated service and leadership in their field, NAI’s network of demanding, discriminating customers truly is world-class—and appreciative.

“I can’t say enough about you guys. If all my vendors were like NAI, my job would be a lot easier! Very quick and timely response to all issues and always seem to be on top of a program!”

–Mike Barbour, Sr. Subcontracts Manager, Raytheon GBS

“We love your products. I’ll be looking to see how your new products can solve our next problems.”

George Camann – Software Engineer Manager, Calspan Corporation, Flight Research Group

COSA® architecture (Configurable Open Systems Architecture™)

One of the keys to NAI’s success has been enabling their customers to leverage NAI’s modular and adaptable COSA® architecture, providing them with application-ready systems for harsh air, land and sea environments plagued by, for example:

- Shock and vibration

- Extreme temperature, humidity/wetness

- Corrosion or abrasion

- Electromagnetic interference

- Low pressure/altitude

- Dust

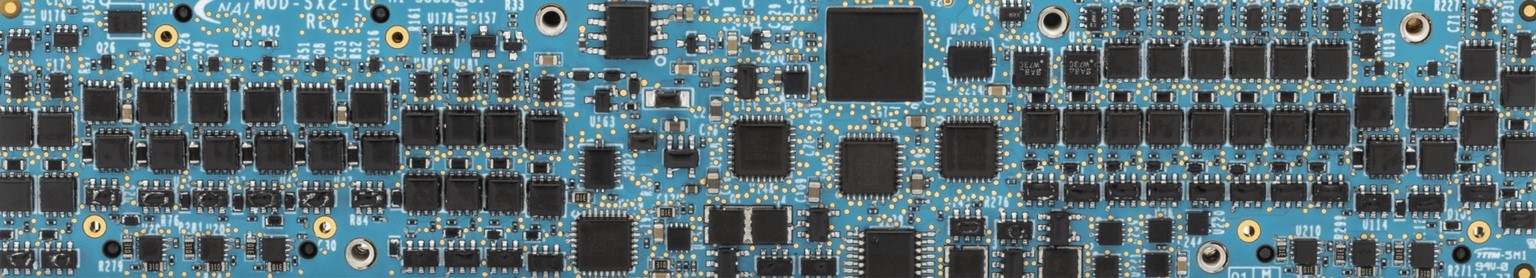

COSA® gives NAI customers the most modular, agile and rugged COTS (commercial off-the-shelf) portfolio of embedded smart modules, I/O boards, single-board computers, power supplies and ruggedized systems on the market. All are pre-engineered to work together today—and can be easily changed, reused or re-purposed down the road. NAI has used FPGAs and SoCs to create smart modules that enable their customers to rapidly create configurable mission systems—while reducing or eliminating SBC overhead.

Accelerate your time to mission with COSA®.

COTS systems

NAI’s rugged COTS, pre-configured and tested systems are unequalled and allow rapid deployment with less risk, and no NRE (non-recurring engineering). They are also SWaP optimized—striking a fine balance between size, weight, and power that gives users the edge in highly competitive real-world scenarios.

North Atlantic Industries’ COSA® family of products

NAI’s COSA® family of products comprises the most modular, agile and rugged portfolio of embedded I/O modules boards, systems and power supplies of their kind.

Smart function modules

NAI offers more than 70 smart, field-proven function modules covering a wide variety of I/O, measurement and simulation, communications, ethernet switch and SBC functions.

IO boards and SBCs

NAI offers a variety of rugged embedded boards—both multifunction IO cards and single board computers in OpenVPX, cPCI, VME and PCI/PCIe form factors.

Power supplies

NAI designs and manufactures a full line of COTS, modified COTS and custom power supplies—including configurations that meet VME, cPCI and VPX (VITA 62) requirements.

Rugged systems

NAI’s rugged systems are designed to provide fast, fail-safe access to sensor-based information in the harshest military environments while optimizing SWaP (size, weight and power) requirements.

To learn more about North Atlantic Industries’ products and find the right one for your application, please view Integrys’ NAI inventory.

About Integrys

About Integrys

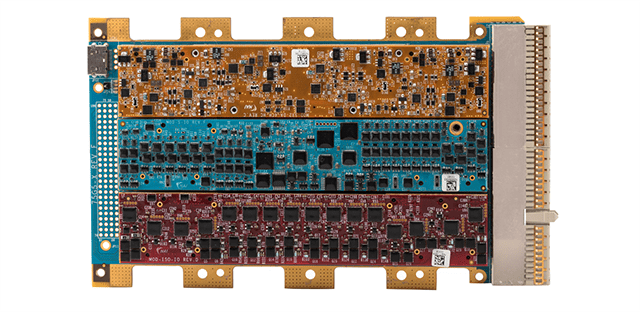

BOHEMIA, NY – October 2019 — North Atlantic Industries, Inc. (NAI), a leading supplier of embedded computing solutions and power supplies, has leveraged its modular and adaptable Configurable Open Systems Architecture ™ (COSA®) and Nano Interface Units (NIU) to introduce application-ready Nano Remote Data Concentrators. With an extremely small footprint of 7.0” x 3.0” x 2.5” and weighing less than 3 lbs. these small, low-power units deliver off-the-shelf solutions that accelerate deployment of SWaP-optimized systems — in less time, with NO NRE.

BOHEMIA, NY – October 2019 — North Atlantic Industries, Inc. (NAI), a leading supplier of embedded computing solutions and power supplies, has leveraged its modular and adaptable Configurable Open Systems Architecture ™ (COSA®) and Nano Interface Units (NIU) to introduce application-ready Nano Remote Data Concentrators. With an extremely small footprint of 7.0” x 3.0” x 2.5” and weighing less than 3 lbs. these small, low-power units deliver off-the-shelf solutions that accelerate deployment of SWaP-optimized systems — in less time, with NO NRE.