Answering the question “What is deep learning?” requires us to stick our heads down a rabbit hole. We say this because deep learning is a type of machine learning—which, in turn, is a type of artificial intelligence (AI). You now get the reference to the rabbit hole . . . Time now for some definitions to provide clarity.

Artificial intelligence: The simulation of human intelligence in machines that are programmed to think like humans and mimic their actions. The term may also be applied to any machine that exhibits traits associated with a human mind, such as learning and problem-solving.

Machine learning: The use and development of computer systems (hardware and software) that are able to learn and adapt without following explicit instructions, by using algorithms and statistical models to analyze and draw inferences from patterns in data.

Deep learning: A subset of machine learning based on artificial neural networks in which multiple layers of processing are used to extract progressively higher level features from data.

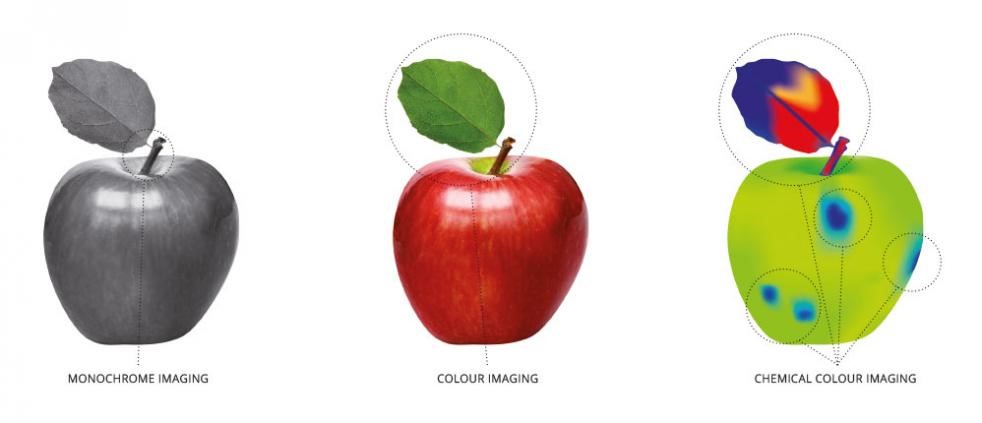

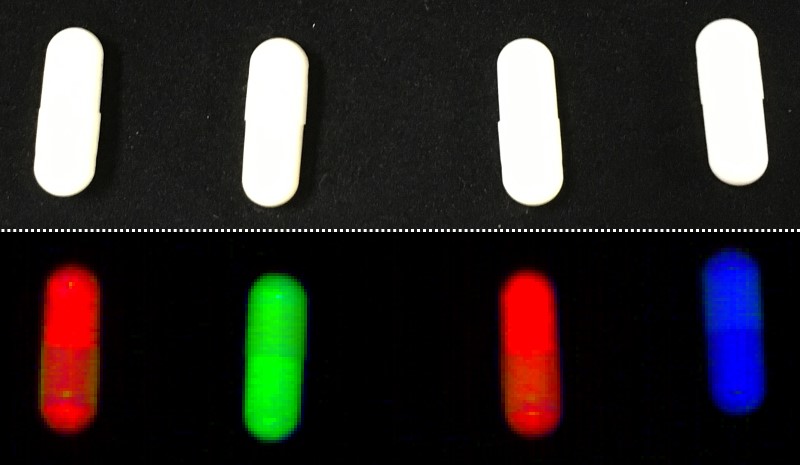

What distinguishes deep learning is that it empowers machines to learn from unstructured, unlabeled data, as well as labeled and categorized data. With all the rapid developments in deep learning, a lot of new applications for machine vision have been introduced. Time now for another definition:

Machine vision: The technology and methods used to provide imaging-based automatic inspection and analysis for such applications as automatic inspection, process control, and robot guidance, usually in industry. Machine vision refers to many technologies, software and hardware products, integrated systems, actions, methods and expertise. A machine vision system uses a camera to view an image. Computer vision algorithms then process and interpret the image, before instructing other components in the system to act upon that data. Computer vision can be used alone, without needing to be part of a larger machine system.

GPUs for computer vision applications

Many technology companies have discovered the benefit of using GPUs (Graphical Processer Units) for computer vision applications due to their ability to handle the rapid parallel processing of images. Traditional GPUs from companies like NVIDIA are large, power-hungry PCIe boards running in the cloud or temperature-conditioned environments. So how do industrial companies take advantage of GPU technology in the field, or what’s often called ‘the edge’?

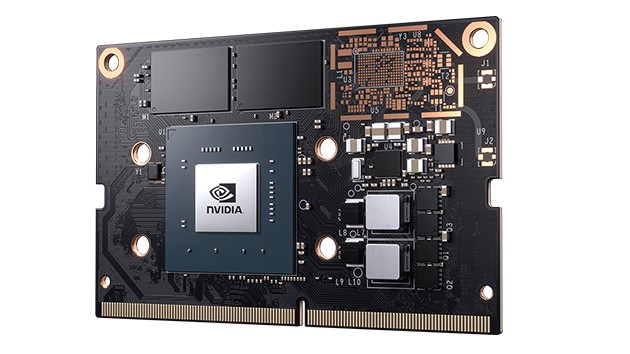

NVIDIA Jetson

Introducing NVIDIA Jetson, the world’s leading small-footprint GPU platform for running AI in harsh environments at the edge of the action. Its high-performance, low-power computing for deep learning and computer vision makes it the ideal platform for compute-intensive projects in the field. Some of Integrys’ most valued partners provide nimble solutions in this space. But before we look at these companies and their products, it’s advisable to ask, and answer, the question below.

What’s the difference between carriers and Jetson modules?

A carrier board is specifically designed to work with one of the NVIDIA Jetson modules allowing users to connect IO, cameras, power, etc., to their devices. Together with JetPack SDK, the combination of the carrier and module is used to develop and test software for specific use needs.

Our Deep Learning Partners

|

|||

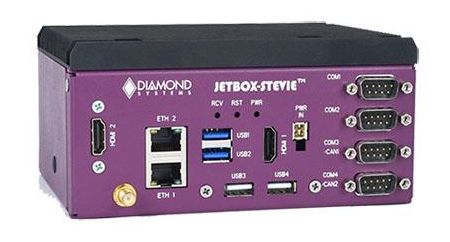

| Stevie: Carrier for Nvidia Jetson AGX Xavier. Used in PPE and temperature monitoring, robotics, deep learning, and smart intersections/ traffic control.

Featured product: JETBOX-STEVIE JETSON AGX XAVIER SYSTEM

|

Floyd: Carrier for Nvidia Jetson Nano & Xavier NX. Used in industrial safety, drone video surveillance and facial recognition.

Featured product: JETBOX-FLOYD JETSON NANO / NX SYSTEM

|

||

|

|||

| Sentry-X Rugged Embedded System: Built for the NVIDIA® Jetson AGX Xavier™, Sentry-X is ideal for aerospace and defense applications, or for any market that can benefit from the Jetson AGX Xavier’s incredible performance in a rugged enclosure.

Featured product: SENTRY-X RUGGED EMBEDDED SYSTEM POWERED BY NVIDIA® JETSON AGX XAVIER™

|

Rogue: a full featured carrier board for the NVIDIA® Jetson™ AGX Xavier™ module, the Rogue is specifically designed for commercially deployable platforms, and has an extremely small footprint of 92mm x 105mm.

Featured product: ROGUE CARRIER FOR NVIDIA® JETSON™ AGX XAVIER™

|

||

|

|||

| Leveraging convolutional neural network (CNN) technology, the Matrox classification tool within their Computer Vision library, MIL (Matrox Imaging Library) categorizes images of highly textured, naturally varying, and acceptably deformed goods. The inference is performed exclusively by Matrox Imaging-written code on a mainstream CPU, eliminating the dependence on third-party neural network libraries and the need for specialized GPU hardware.

|

Featured product: MATROX IMAGING LIBRARY X |

||

|

|||

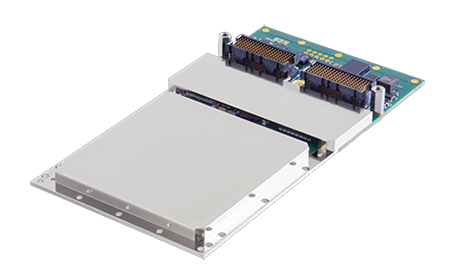

| The Condor product line of GPGPU and video capture cards feature NVIDIA Quadro® GPUs with Pascal™ and Turing™ architecture. These processing powerhouses leverage the latest GPGPU advancements from NVIDIA for machine-learning and artificial intelligence applications, as well as standard rendering pipelines.

|

Featured product: CONDOR 4107XX XMC XMC GRAPHICS & GPGPU CARD |

||

|

|||

|

|||