A leader in the machine vision industry, Matrox® Imaging leverages our vision expertise to apply deep learning technology when and where most appropriate and help our customers find the best solution for their applications. Artificial intelligence, specifically machine learning by way of deep learning, is making machine vision technology for automated visual inspection more accessible and capable. Deep learning technology mimics how the human brain processes visual input but performs this task with the speed and robustness of a computerized system. The technology works to ensure quality in manufacturing industries, controlling production costs and enhancing customer satisfaction.Deep learning technology excels at certain applications, such as identification and defect detection, specifically in instances where there are complex and varying imaging conditions. The technology still benefits from conventional image processing and analysis to locate regions of interest within images to speed up the overall process and make it even more robust. Artificial intelligence, specifically machine learning by way of deep learning, is making machine vision technology for automated visual inspection more accessible and capable. Deep learning technology mimics how the human brain processes visual input but performs this task with the speed and robustness of a computerized system. The technology works to ensure quality in manufacturing industries, controlling production costs and enhancing customer satisfaction.Deep learning technology excels at certain applications, such as identification and defect detection, specifically in instances where there are complex and varying imaging conditions. The technology still benefits from conventional image processing and analysis to locate regions of interest within images to speed up the overall process and make it even more robust.

Real-world examplesDeep learning software and hardware

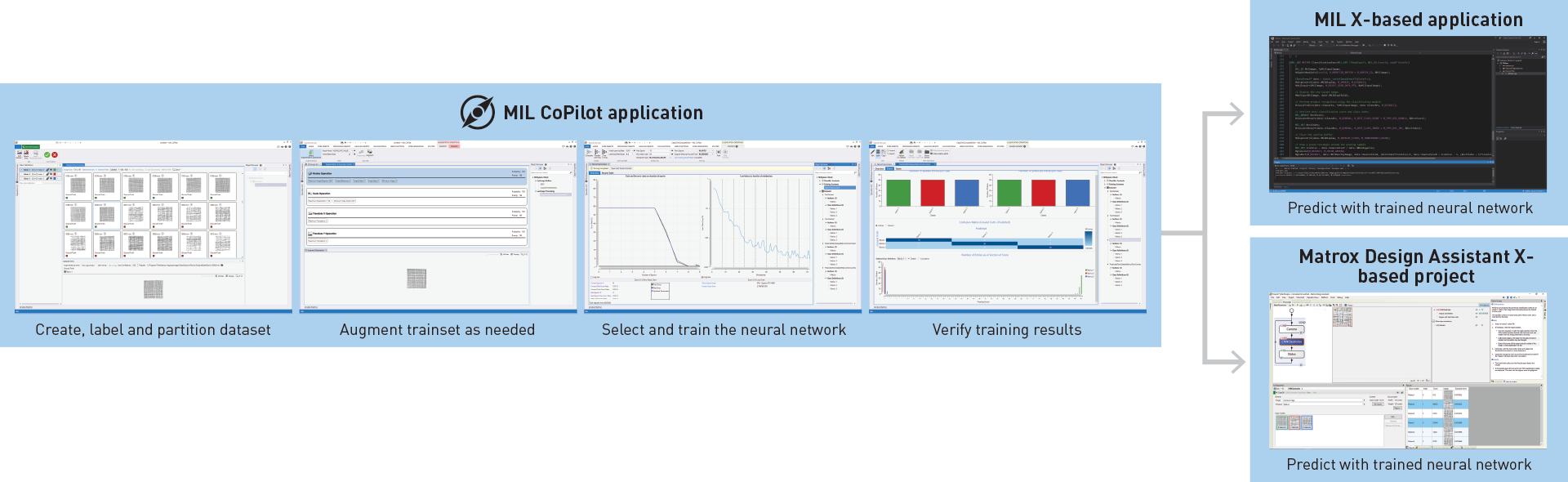

Matrox Imaging’s software offerings—Matrox Imaging Library (MIL) X and Matrox Design Assistant® X—include vision tools to classify or segment images for inspection using deep learning. Both software packages deliver optimized convolutional neural networks (CNNs) or models for the task.

Key to deep learning is the training of a neural network model. MIL CoPilot’s interactive environment provides the platform for training these models for use in machine vision applications. MIL CoPilot delivers all the functionality needed for this task, so you can create and label the training image dataset; augment the image dataset, if necessary; and train, analyze, and test the neural network model.

e also offer hardware products that facilitate deep learning training and deployment. A suitably equipped and configured model of the Matrox 4Sight XV6 industrial computer comes ready for deep learning training. Another Matrox 4Sight XV6 model as well as the Matrox 4Sight EV6 vision controller and Matrox Iris GTX smart cameras are available to run both traditional machine vision workloads as well as deep learning inference.

|