The use of artificial intelligence (specifically, machine learning by way of deep learning) in machine vision is an incredibly powerful technology with an impressive range of practical applications, including:

- Giving virtual assistants the ability to process natural language;

- Enhancing the e-commerce experience through recommendation engines;

- Assisting medical practitioners with computer-aided diagnoses; and

- Performing predictive maintenance in the aerospace industry.

Deep learning technology is also fundamental to the fourth industrial revolution, the ongoing automation of traditional manufacturing and industrial processes with smart technology, a movement in which machine vision has much to contribute.

Deep learning alone, however, cannot tackle all types of machine vision tasks, and requires careful preparation and upkeep to be truly effective. In this article we look at how machine vision—the automated computerized process of acquiring and analyzing digital images primarily for ensuring quality, tracking and guiding production—benefits from deep learning as the latter is making the former more accessible and capable.

Machine vision and deep learning: The challenges

Machine vision deals with identification, inspection, guidance and measurement tasks commonly encountered in the manufacturing and processing of consumer and industrial goods. Conventional machine vision software addresses these tasks with specific algorithm and heuristic-based methods, which often require specialized knowledge, skill and experience to be implemented properly. Moreover, these methods or tools sometimes fall short in terms of their ability to handle and adapt to complex and varying conditions. Deep learning is of great help but requires a painstaking training process based on previously collected sample data to produce results generally required in industry. Furthermore, more training is occasionally needed to account for unforeseen situations that can adversely affect production. It is important to appreciate that deep learning is primarily employed to classify data and not all machine learning tasks lend themselves to this approach.

Where deep learning does and does not excel

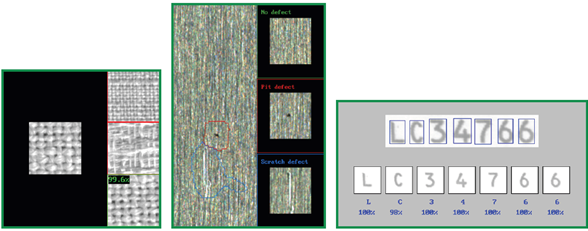

As noted, deep learning is the process through which data—such as images or their constituent pixels—are sorted into two or more categories. Deep learning is particularly well suited to recognizing objects or objects traits, such as identifying that widget A is different from widget B The technology is also especially good at detecting defects, whether the presence of a blemish or foreign substance, or the absence of a critical component in or on a widget that is being assembled. It also comes in handy for recognizing text characters and symbols such as expiry dates and lot codes.

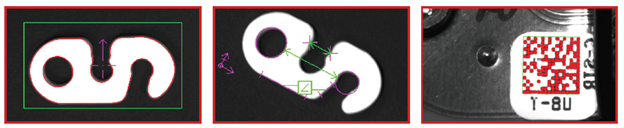

While deep learning excels in complex and variable situations such as finding irregularities in non-uniform or textured image backgrounds or within an image of a widget whose presentation changes in a normal and acceptable manner, deep learning alone cannot locate patterns with an extreme degree of positional accuracy and position. Analysis using deep learning is a probability based process and is, therefore, not practical or even suitable for jobs that require exactitude. High-accuracy, high-precision measurement is still very much the domain of traditional machine vision software. The decoding of barcodes and two-dimensional symbologies, which is inherently based on specific algorithms, is also not an area appropriate for deep learning technology.

Where deep learning does not excel: High-accuracy, high-precision pattern matching (left), metrology (middle), and code reading (right)

Matrox Imaging software

Matrox Imaging offers two established software development packages that include classic machine vision tools as well as image classification tools based on deep learning. Matrox Imaging Library (MIL) X is a software development kit for creating applications by writing program code. Matrox Assistant X is an integrated development environment where applications are created by constructing and configuring flowcharts (see graphic below). Both software packages include image classification models that are trained using the MIL CoPilot interactive environment, which also has the ability to generate program code. Users of either software development packaged get full access to the Matrox Vision Academy online portal, offering a collection of video tutorials on using the software, including image classification, that are viewable on demand. Users can also opt for Matrox Professional Services to access application engineers as well as machine vision and machine learning experts for application-specific assistance.