Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

Industrial

Integrys provides solutions that reduce costs while increasing productivity and efficiency.

The manufacturing sector is faced with the challenge of making ongoing improvements to cycle times, material yield, up time, and product quality. For many companies, this means more automation, better process control, rugged displays, and greater equipment reliability.

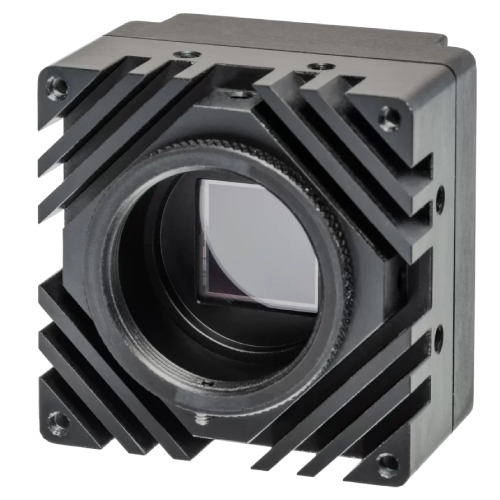

And, because margins are shrinking, the technology budgets to do this are tight. Integrys thrives in this kind of environment. We are ideal automation partners, with strong connections to leading component manufacturers, plus strong in-house engineering capabilities. We can select and engineer a diverse range of automation solutions, including machine-vision systems for process control and quality monitoring.

In fact, vision systems are an Integrys specialty. Our imaging solutions are used for control quality, and to monitor process flows, improve yield, and increase productivity. Integrys engineered a leather cutting solution for one of our OEM customers that scans a hide, calculates surface area, and detects flaws. It then plots the maximum possible number of pieces from the hide. A lumber mill solution co-developed with our OEM partner uses similar logic to maximize the board feet cut from a single log. This cooperation with our OEM customer allowed them to go to market early and capitalize on immediate opportunities.

Integrys’ documentation meets the requirements of ISO and other quality systems. So every solution we engineer is available with fully compliant, as-built, and version-control documentation.

Reliability is critical in manufacturing systems. Integrys works only with dependable suppliers and offers supply-chain management services for the components and parts we sell.