Whether you are updating your current computers or buying them for a new facility or operation, given the wide selection of products on the market, figuring out the right ones for your company’s specific operations and working environments can be a daunting task. After all, rugged computers are much more than just hard shells . . . This article examines some of the criteria that you should weigh when assessing computers for your challenging—and sometimes nasty—work environments.

Analyzing your rugged computer tasks

One of the first things you want to do is to conduct a detailed analysis of the tasks for which you will be deploying your rugged computers. This requires an assessment of the full range of:

1) Functions your computers need;

2) Environments and environmental challenges that they will face. Some of the questions to ask on this front include:

- What is the operational temperature range?

- For what environmental elements—liquids, dust, salt, etc.—is ingress protection required?

- What vibration and shock might be encountered?

- Is magnetic interference a factor?

- What about pressure/altitude?

- What are the size and weight constraints?

- Are the screen(s) easy to read in bright sunlight?

Depending on the industry in which your company operates, you are likely to benefit by choosing a computer compatible with industry-specific applications and software. This entails choosing a device that runs the correct operating system for the specific application or software you’re planning to install. You might also choose a device with the software you require pre-installed. This is the case with the Matrox 4Sight EV6 vision controller, a powerful industrial imaging computer for managing multi-camera inspections efficiently and with ease. The Matrox 4Sight EV6 comes with the Matrox Imaging Library (MIL), pre-installed, allowing it to be deployed almost immediately.

Accelerating time to mission is also one of the assets of North Atlantic Industries’ commercial off-the-shelf (COTS) 3U cPCI single board computers. Designed for rugged defense, commercial aerospace, and industrial applications, these rugged computers eliminate man-months of integration.

Rugged computer specifications

Analysis of the tasks for which your computers will be used, and of the environmental challenges, will help you determine the specifications of the computers you require. In this endeavour you may find yourself walking a fine line. On the one hand you want computers with specs that make them sufficiently rugged to perform optimally for a number of years in your challenging work environments—and that provide adequate protection of the valuable data that you obtain with them, as well as for the recovery of lost information; on the other hand, you don’t want to pay for rugged features that you don’t require. Investing in rugged computers can be a significant investment and buying a high-end Lexus when you only need a Corolla can impact the profitability of your operations. You’ve got to find the right balance between price and performance.

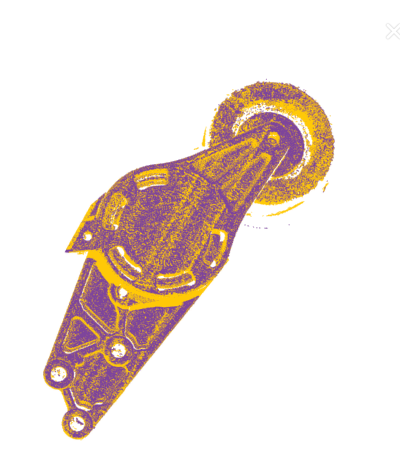

The SabreCom series of rugged mission computers: bringing an exciting level of price/performance to the market

Rugged computing partners

Making decisions about the specs requires research into the manufacturers of rugged computers and gives rise to the question of whether you can take advantage of off-the-shelf models or whether you require a degree of customization. It also brings up key, non-technical issues. Buying rugged computers means entering into a relationship with the companies that design and manufacture them, or with companies, such as Integrys, that promote and support manufacturers’ products in the marketplace. Having the right partner in place can help you make the purchase and deployment happen on schedule and on budget—with end user satisfaction that helps raise productivity.

Testing rugged computers

Good partners help you avoid mistakes. And in the world of rugged computing it would be a serious mistake to make a purchase without giving employees who use them an opportunity to thoroughly test them in real-world situations—possibly in multiple situations/locations over an extended period of time. In most cases, testing in the lab is not sufficient. Feedback from your employees telling you that the computers they have been putting through the paces in the field are intuitive/easy-to-use and sufficiently robust and reliable is your best guarantee that you are making a sound business decision.

You need a partner that can work with you. It’s not just the hardware that will help you keep your employees focused on the job. Are your partners in the purchase amenable to you conducting the field testing that you consider necessary before making a commitment?

Warranty

All rugged computers come with a warranty. To optimize your investment it is essential that you fully understand the terms of your warranty.

Contact us

Click here to learn more about Integrys’s rugged computer offerings.