Description

The Zebra® 4Sight EV7 is an advanced industrial imaging computer tailored to excel in multi-camera vision applications on factory floors. Built upon a rich legacy of success, this evolutionary imaging computer boasts a twelfth-generation twelve-core Intel® Core™ processor, complete with deep learning inference and prediction acceleration. What sets it apart is its fanless design, ensuring a reliable and quiet operation, making it the perfect fit for any production facility, whether monitoring a single line or multiple production lines.

Optimized for multi-camera installations, the Zebra 4Sight EV7 is equipped with four 2.5 Gigabit Ethernet and four SuperSpeed USB ports, seamlessly connecting to a wide array of GigE Vision® and USB3 Vision® cameras. The Gigabit Ethernet ports even support Power over Ethernet (PoE), simplifying cabling and reducing costs when compatible GigE Vision cameras are used.

Flexibility is at the core of the Zebra 4Sight EV7 vision controllers, supported by two comprehensive software platforms: Aurora Design Assistant®, formerly Matrox Design Assistant (DA), and Aurora Imaging Library, formerly Matrox Imaging Library (MIL). With Aurora Design Assistant’s flowchart-based integrated development environment (IDE) and Aurora Imaging Library’s software development kit (SDK), engineers and technicians can effortlessly configure and deploy machine vision applications, covering various operations such as video capture, analysis, classification, measurement, reading, verification, communication, and I/O operations.

Interfacing with other industrial equipment and integrating with enterprise systems is a breeze for the Zebra 4Sight EV7. It features RS-232/RS-485 ports for legacy automation device connections and two additional Gigabit Ethernet ports for independent connections to industrial and enterprise networks. Notably, one of these networking ports includes a hardware-assisted mechanism for PROFINET® communication, ensuring timely responses even during short cycle-times or heavy processor loads.

The Zebra 4Sight EV7 is engineered with industrial-strength design, eliminating the need for air filters or fans due to its fanless operation. Its compact footprint, rugged casing, and wide ambient operational temperature range make it suitable for mounting in harsh, space-limited environments. Moreover, carefully selected components guarantee consistent long-term availability, maximizing the return on your original investment.

For real-time discrete I/O management, the Zebra 4Sight EV7 features a dedicated hardware-assisted mechanism, enabling precise output events based on elapsed time, specific input events, or count-derived inputs, including those from rotary encoders. The computer’s ability to manage multiple cascadable hardware timers ensures effective synchronization of vision applications with manufacturing lines.

In summary, the Zebra® 4Sight EV7 stands out as a powerful and reliable fanless imaging computer, tailored to meet the demands of multi-camera vision applications in industrial settings. With its robust design, seamless connectivity options, and real-time I/O management capabilities, it is a wise investment for businesses seeking to optimize their imaging processes on the factory floor.

Features of 4Sight EV7 Fanless Imaging Computer:

1. Fanless Design: Quiet and reliable operation, reducing maintenance and noise concerns.

2. Connectivity: Four 2.5 Gigabit Ethernet and four SuperSpeed USB ports for seamless camera connections.

3. Power over Ethernet (PoE) Support: Simplifies cabling and reduces costs for compatible GigE Vision cameras.

4. Aurora Design Assistant®: Flowchart-based IDE for quick configuration and deployment of machine vision applications.

5. Aurora Imaging Library: SDK for traditional programmers developing machine vision applications.

6. Industrial Interfaces: RS-232/RS-485 ports and additional Gigabit Ethernet ports for versatile connections.

7. PROFINET® Communication: Hardware-assisted mechanism for efficient automation control.

8. Rugged Build: Designed to withstand harsh environments, mountable horizontally or vertically.

9. Long-Term Availability: Carefully selected components ensure consistent availability and maximize return on investment.

Benefits of 4Sight EV7 Fanless Imaging Computer:

1. Reliable & Quiet: Fanless design ensures noise-free operation, reducing maintenance and creating a peaceful environment.

2. Versatile Connectivity: Four 2.5G Ethernet & USB ports connect effortlessly to GigE Vision® & USB3 Vision® cameras.

3. Cost-Effective Cabling: Gigabit Ethernet ports support PoE, simplifying cabling and lowering costs.

4. Easy Application Deployment: Comprehensive software platforms for quick configuration & deployment of vision applications.

5. Seamless Industrial Integration: Equipped with RS-232/RS-485 & additional Gigabit Ethernet ports for smooth interfacing.

6. Timely Communication: Hardware-assisted PROFINET® mechanism ensures efficient communication during high workloads.

7. Robust & Rugged Design: Industrial-grade, fanless design with wide temperature range for harsh environments.

8. Long-Term Availability: Carefully selected components ensure consistent availability, maximizing ROI.

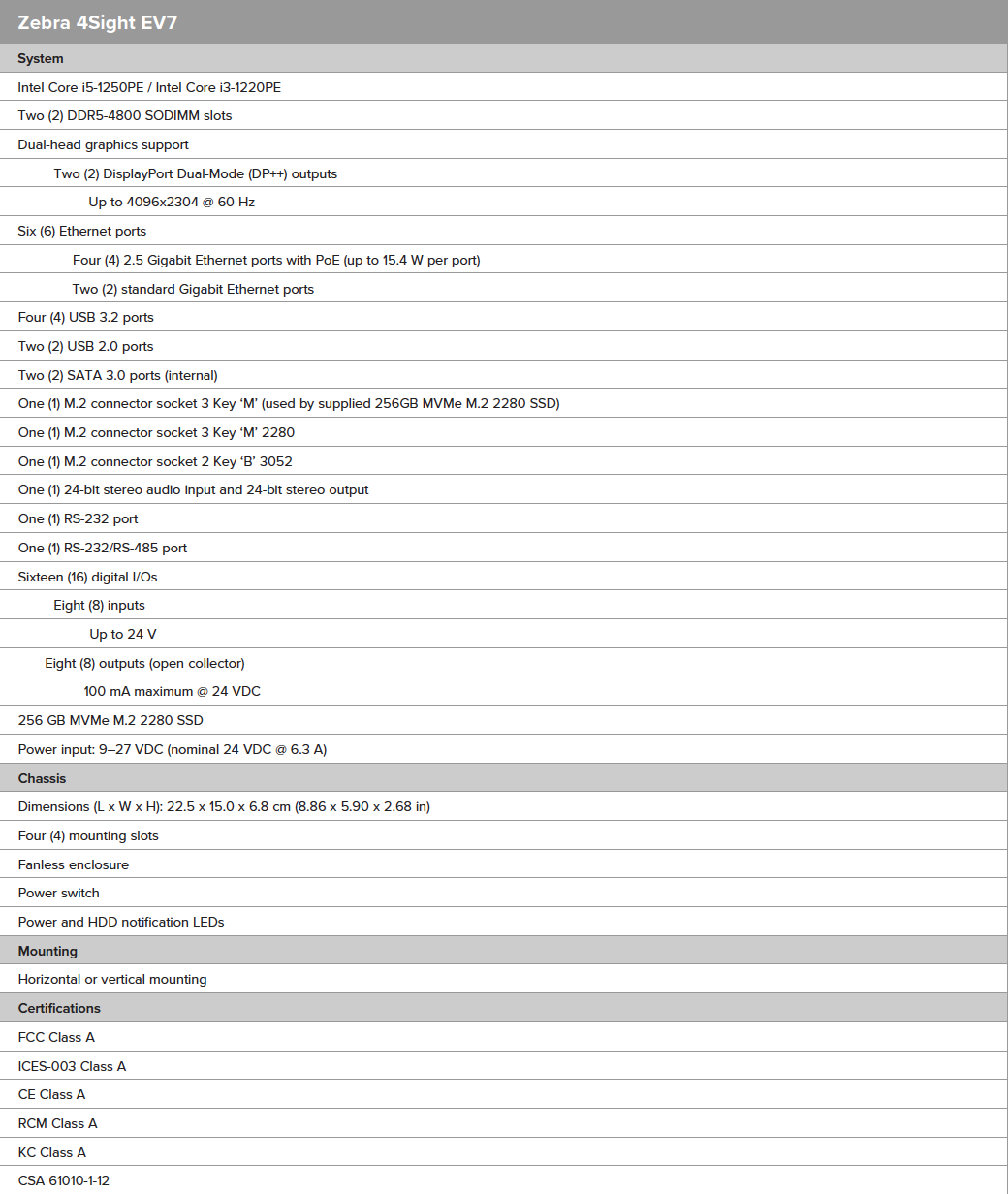

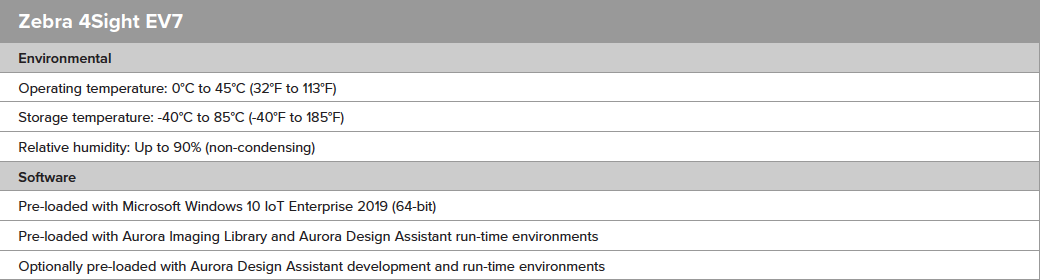

Specifications:

Click Here to view more from Zebra Technologies.